- 18650 batteries with GEN3 silicon-anode materials demonstrate a 30% cumulative energy return compared to graphite benchmark batteries during and up to the 650 cycle tests [1].

- The Gen3 batteries delivered 2,296 Ampere-Hour (Ah) of cumulative energy return, compared to graphite benchmark batteries that only deliver 1,766 Ah.

MONTREAL, Canada — HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials, is pleased to update shareholders on the latest battery milestones achieved by its France-based affiliate, NOVACIUM SAS (Novacium).

The latest results confirmed that, over 650 cycles, 18650 batteries made with Novacium’s GEN3 silicon-based anode material delivered a cumulative energy return of 2,296 Ampere-Hours (Ah), while graphite benchmark batteries made with high-grade artificial graphite delivered only 1,766 Ah—representing a 30% cumulative energy gain.

TESTING CONFIRMS GEN3 SILICON-ANODE PERFORMANCE

To achieve this data, we conducted rigorous testing protocols [2] on lithium-ion 18650 batteries. Two sets of three batteries were tested: one made with a blend of the same high grade artificial graphite and Novacium’s GEN3 silicon-based anode material, and the other serving as a graphite benchmark. We then calculated the cumulative energy return of the current discharged by each battery over the 650 cycles and compared the results.

“These latest results validate the performance of our GEN3 silicon-based anode technology, and underscores its readiness for real-world applications,” said Dr. Jed Kraiem, COO of Novacium. “The results demonstrate a clear path to significantly improving energy density and battery lifespan while maintaining compatibility with existing manufacturing processes.”

“Our analysis further indicates that targeted process refinements could unlock even greater performance gains and minimize long-term degradation, paving the way for next-generation lithium-ion batteries,” added Mr. Kraiem.

BATTERY PERFORMANCE AND COULOMBIC EFFICIENCY WITH SILICON-ANODES AT 650 CYCLES

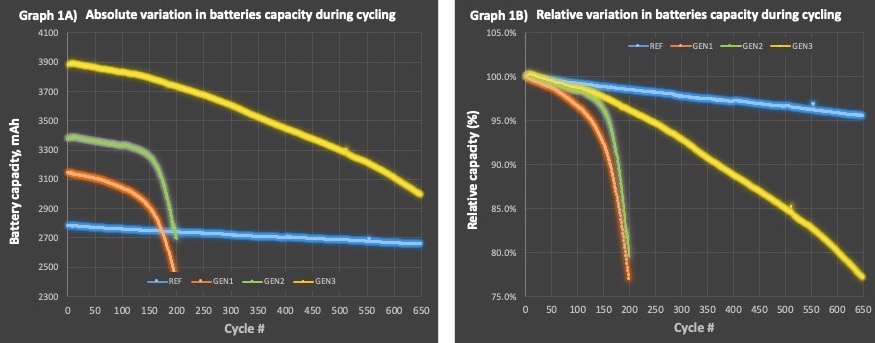

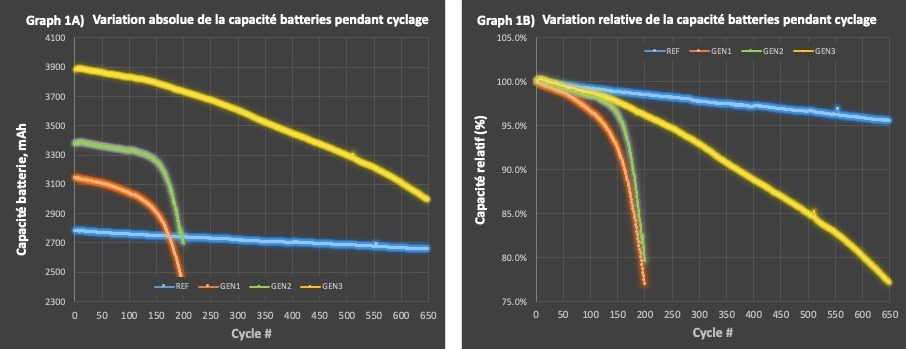

Graph 1A illustrates the average capacity (in mAh) of three 18650 batteries made utilizing Novacium’s GEN3 silicon-based material (yellow line) compared to the average capacity of the 100% high grade artificial graphite benchmark batteries (blue line). At 650 cycles, the three GEN3 batteries demonstrate an average capacity of 3,000 mAh, which exceeds the graphite benchmark’s 2,656 mAh by 13%.

Graph 1B presents the relative capacity retention (or Coulombic efficiency [3]) of three 18650 batteries utilizing Novacium’s GEN3 material (yellow line) compared to the 100% high grade artificial graphite benchmark batteries (blue line) over 650 cycles. The key take away from these results is that the GEN3 batteries retain an average of 77% capacity at 650 cycles. This marks a significant improvement over the rapid degradation observed with previous GEN1 and GEN2 materials, further showcasing a notably more stable degradation profile—an encouraging step forward in material performance.

Finally, further analysis of the data suggests that minor process modifications could reduce degradation by at least 13 percent after 650 cycles.

“These results demonstrate our ability to produce a silicon-based anode material that delivers between 3,000 mAh and 3,355 mAh at 650 cycles, with Coulombic efficiency ranging from 77% to 87%,” Dr. Kraiem commented on the analysis. “The capacity and durability achieved so far are highly encouraging, and we have a clear path to further improvements.”

“Our battery material offers practical solutions for market participants, driving the growing interest we’re seeing across industries,” said Bernard Tourillon, President and CEO of HPQ Silicon Inc. and NOVACIUM SAS. “By advancing our proprietary processes, we are leveraging the battery expertise and silicon anode innovations developed throughout 2024 to deliver materials with low operating costs, minimal carbon footprints, and exceptional performance.”

“This positions HPQ and NOVACIUM as key players in next-generation energy solutions that meet the industry’s performance and sustainability goals, added Mr. Tourillon.

REFERENCE SOURCES

[1] Novacium technical team analysis of the data from the ongoing charging and discharging cycle tests conducted at a world-leading university, the name of which is kept confidential for competitive reasons.

[2] Cycling parameters from: Ratnakumar Bugga et al. “Performance of Commercial High Energy and High Power Li-Ion Cells in Jovian Missions Encountering High Radiation Environments”, NASA Battery Workshop November 19-21, 2019.,

[3] Link to information on Coulombic efficiency.