- 18650 batteries with GEN3 silicon-based materials continue to deliver 3,606 mAh of capacity after 300 cycles. [1]

- 20% higher than the advertised 3,000 mAh capacity of a new MuRata’s high-performance US18650VTC6 battery. [2]

- On Track to Set a New Performance Standard.

MONTREAL, Canada — HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials, is pleased to update shareholders on the latest battery milestones achieved by its France-based affiliate, NOVACIUM SAS (“Novacium”).

Rigorous ongoing testing protocols [3] (0.5C cycling at 25°C) reveal that Lithium-ion 18650 batteries using a blend of graphite and Novacium’s GEN3 silicon-based anode material achieve a 32% capacity improvement and have only 5% of degradation compared to graphite benchmarks at the 300-cycle mark.

“These results continue to demonstrate the potential of our technology to significantly enhance energy density and extend the lifespan of lithium-ion batteries,” said Dr. Jed Kraiem, COO of Novacium. “Assuming the observed degradation trends continue beyond 300 cycles, our projection models indicate that by around the 1,000-cycle mark, the GEN3 material’s performance should equal the projected graphite benchmark performance at that stage [4].”

BOOSTING BATTERY PERFORMANCE AND COULOMBIC EFFICIENCY WITH SILICON-BASED ANODES AT 300 CYCLES

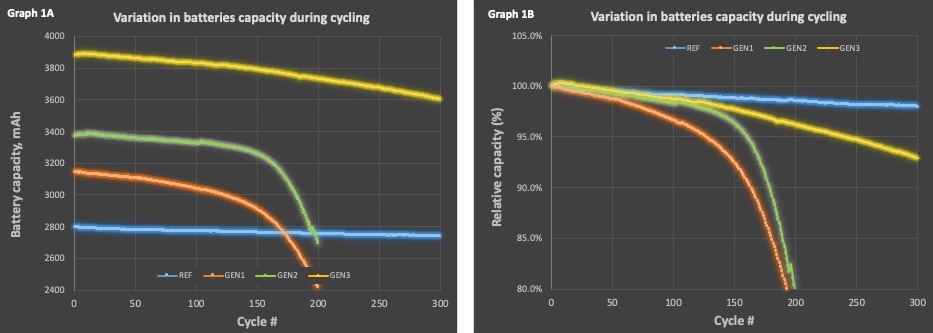

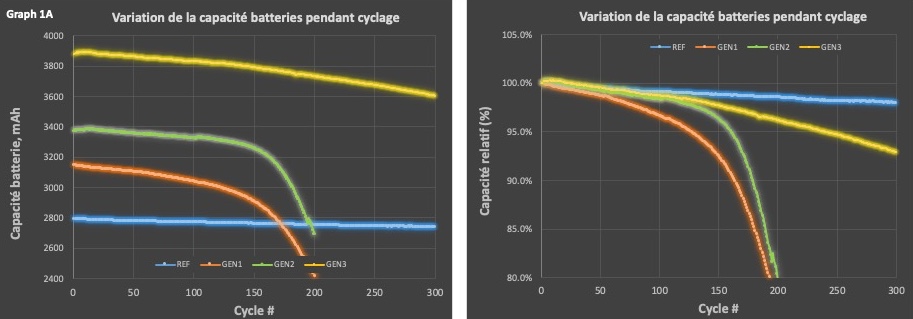

Graph 1B) The green and orange lines show the relative capacity of the GEN1 & GEN2 batteries over 200 cycles, while the blue and yellow lines show the relative capacity of the 100% graphite batteries & the GEN 3 batteries over 300 cycles [1].

Graph 1B) Les lignes orange et verte montrent la capacité relative des batteries GEN 1 & GEN2 sur 200 cycles alors que les lignes bleue et jaune montrent la capacité relative des batteries 100 % graphite & GEN3 sur 300 cycles [1].

Graph 1A highlights the superior capacity (in mAh) of 18650 batteries made with Novacium’s GEN3 material (yellow line) compared to the 100% graphite benchmark (blue line) over 300 cycles. Batteries utilizing GEN2 (green line) and GEN1 (orange line) materials, on the other hand, fail to maintain performance beyond the 200-cycle mark. At 300 cycles, the data shows that GEN3 batteries sustain an average capacity of 3,606 mAh, significantly outperforming the graphite benchmark’s 2,740 mAh.

Graph 1B provides a closer look at the performance degradation (or Coulombic efficiency [5]) of the GEN3 silicon material over 300 cycles, showing a capacity retention of 93% compared to the graphite benchmark’s 98%—a modest 5% difference. Specifically, the absolute capacity of GEN3 batteries (yellow line) decreased from 3,883 mAh to 3,606 mAh, while the graphite benchmark (blue line) exhibited a slight reduction from 2,780 mAh to 2,740 mAh.

The data in Graph 1B reveals that between the 200 and 300-cycle mark, batteries using the graphite benchmark experienced only a 0.6% capacity degradation (from 98.6% to 98.0%), while those made with Novacium’s GEN3 material showed a 3.2% drop (from 96.2% to 93.0%). These findings underscore two key points: first, the coulombic efficiency of the graphite benchmark batteries matches the performance of the best 18650 batteries on the market; second, the efficiency trend of GEN3 batteries remains highly promising.

“I am very excited by the fact that the latest results from our graphite benchmark batteries and our partially optimized GEN3 material are attracting interest from participants in the battery anode material industry,” added Dr. Kraiem. “This is a testament to the value of the battery knowledge we have acquired, and the silicon anode materials work we’ve done over the past year.”

HPQ’S PATENT APPLICATION FOR CONTINUOUS SIOX MANUFACTURING MOVES TO PCT NATIONAL PHASE

Silicon Oxide (SiOx), the key starting material in producing GEN3 silicon-based anode materials for batteries, is central to our innovation. HPQ is pleased to announce that the provisional patent application, filed in France in November 2023, for a continuous Silicon Oxide (SiOx) manufacturing process, is advancing to the PCT National Phase. This milestone follows very encouraging feedback from patent examiners who have reviewed our provisional application.

Current industrial SiOx manufacturing processes rely on the volatilization of quartz (SiO₂) and Upgraded Metallurgical Grade Silicon (UMG Si) [6] in reactors. These processes are typically carried out in batches, which limits productivity, increases costs, and leads to higher energy consumption.

HPQ’s new patented process aims to transition to continuous SiOx production, addressing key limitations by tripling productivity, reducing energy consumption by 20%, and lowering costs by 25-30%. Additionally, the process is designed to produce higher-quality silicon-based materials, offering greater homogeneity and less contamination—attributes that are better suited to the battery market while delivering a more favorable carbon footprint [7].

Another notable advantage of the proposed process is that it can be seamlessly integrated into HPQ PUREVAPTM QRR without requiring significant changes to the reactor design, thereby minimizing technological development risks. Additionally, it’s important to note that the selling price of SiOx is approximately 2 to 3 times higher than that of UMG silicon [8].

“Our battery cycling results clearly demonstrate that our silicon-based anode material technology is in an enviable position. The progression of our SiOx patent application to the PCT National Phase marks another significant step forward in developing proprietary processes that will enable HPQ to manufacture silicon-based anode materials with low operating and capital costs, as well as a low carbon footprint,” said Bernard Tourillon, President and CEO of HPQ Silicon Inc. and NOVACIUM SAS. “This could very well position HPQ and NOVACIUM as key players in delivering next-generation energy solutions that meet both performance and sustainability goals for the industry.”

REFERENCE SOURCES

[1] Novacium technical team analysis of the data from the ongoing charging and discharging cycle tests conducted at a world-leading university, the name of which is kept confidential for competitive reasons.

[2] Link to the source of the information on MuRata Manufacturing high-performance US18650VTC6

[3] Cycling parameters from: Ratnakumar Bugga et al. “Performance of Commercial High Energy and High Power Li-Ion Cells in Jovian Missions Encountering High Radiation Environments”, NASA Battery Workshop November 19-21, 2019.,

[4] Novacium’s technical team has used data from the ongoing charge-discharge cycle tests to build a model projecting future battery performance up to 1,000 cycles. These projections will be updated as new cycling results are received.

[5] Link to information on what is Coulombic efficiency.

[6] The purity level of Upgraded Metallurgical Grade Silicon is usually between 3N and 4N.

[7] Rough Order of Magnitude studies conducted by Novacium’s technical team provide initial estimates, which will be updated during a future Pilot Plant phase.

[8] Information provided based on the latest supplier’s quote received.

About NOVACIUM SAS

Novacium is an HPQ – affiliated company that started in Q3 2022. This green technology startup is based in Lyon, France and is a partnership with HPQ and three of France’s leading research engineers, Dr. Jed KRAIEM PhD, Novacium’s Chief Operating Officer (“COO”), Dr. Oleksiy NICHIPORUK PhD, Novacium’s Chief Technical Officer (“CTO”), and Dr. Julien DEGOULANGE PhD, Novacium’s Chief Innovation Officer (“CIO”). Novacium is a new Research and Development company which allows researchers to develop their own technology in high-added-value fields connected to renewable energy and allows HPQ Silicon Inc. a Canadian company, to expand the depth and reach of its technical team to help develop its silicon and new renewable energy projects.