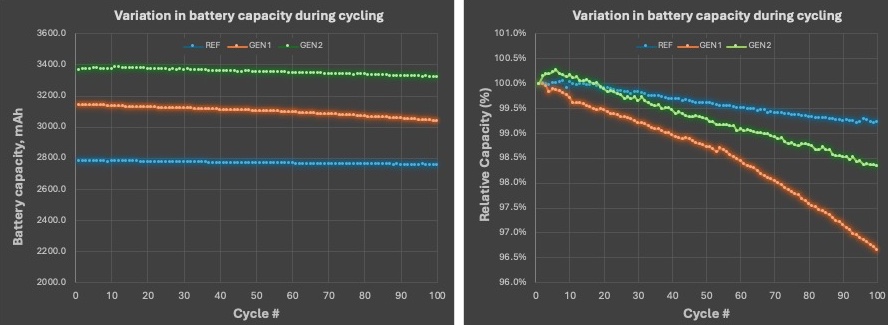

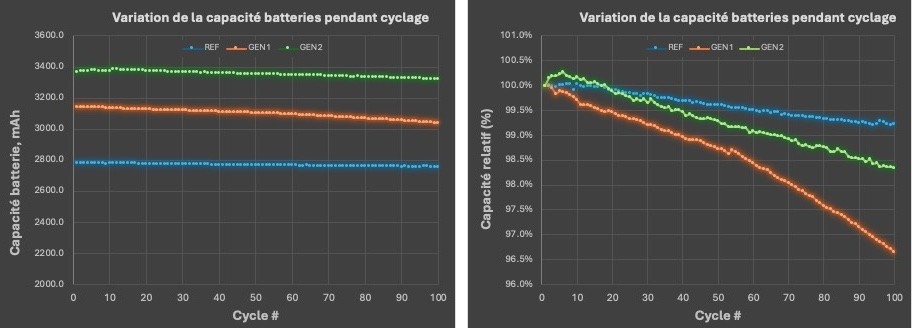

- Testing results after 100 cycles of GEN2 material show continued strong overall capacity improvement compared to the graphite benchmark and GEN1 material, with minimal cycle degradation [1].

MONTREAL, Canada — HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials is pleased to announce the latest battery milestones achieved by its France-based affiliate, NOVACIUM SAS (“Novacium”).

This announcement highlights the continuation of the remarkable results obtained during the cycle tests of 18650 industrial batteries made with Novacium’s non-optimized second-generation advanced silicon-based anode material over 100 cycles.

“These results continue to showcase our capability to produce a blend of graphite and advanced silicon anode material that significantly improves overall battery performance and can be seamlessly integrated into existing anode manufacturing facilities,” stated Dr. Jed Kraiem, Ph.D., COO of Novacium. “However, we are not finished, we intent to continue improving our material so that our third generation of advanced silicon-based material can crack the 4,000 mAh.”

SILICON BASED ANODE MATERIALS UNLOCKING ENHANCED BATTERY PERFORMANCE WITH MINIMAL DEGRADATION

and the green line the relative capacity of GEN 2, over 100 cycles [1].

The graph on the left illustrates the progression in battery capacity over 100 cycles. The blue line represents the average capacity of three (3) 18650 batteries with 100% graphite at around 2,769 mAh. The orange line shows the average capacity of three (3) 18650 batteries using Novacium GEN1 materials at around 3,100 mAh. Finally, the green line depicts the average capacity of three (3) 18650 batteries using Novacium GEN2 materials at around 3,355 mAh.

In the graph on the right, the blue line represents the average relative capacity of three (3) 18650 batteries with 100% graphite; the orange line is the average relative capacity of three (3) 18650 batteries made using Novacium GEN1 materials, and the green line the average relative capacity of three (3) 18650 batteries using Novacium GEN2 materials, over 100 cycles.

These results continue to demonstrate minimal measurable capacity degradation for Novacium GEN2 materials (approximately 1.7%), similar to the graphite benchmark and also show the superior relative capacity retention of the GEN2 materials compared to the GEN1 material (1.7% versus 3.3%).

“These promising results have real-world applications,” stated Mr. Bernard Tourillon, President and CEO of HPQ Silicon Inc. and NOVACIUM SAS. “To illustrate an example of its potential impact, the global cell phone battery market, which is perfectly suited for our anode material, is expected to reach US$38.8 billion by 2030, growing at a CAGR of 6.4% between 2024 and 2031 [2].”

REFERENCE SOURCES

[1] Novacium technical team analysis of the data from the ongoing charging and discharging cycle tests conducted at a world-leading university, the name of which is kept confidential for competitive reasons.

[2] Global Cell Phone Battery Market is expected to reach US$ 38.8 billion by 2030, growing with a CAGR of 6.4% during the forecast period 2024-2031. (Link to source).